Explain Different Process of Powder Metallurgy

The size of the powder largely effects the properties of the part produced. This is followed by heating sintering that causes the.

Powder Metallurgy What Is It Processes Parts Metals Used

Parts from some metals can not be produced with the conventional metal shaping processes.

. The Powder Metallurgy is also abbreviated as the PM. We just covered casting and now well talk about a different manufacturing process called powder metallurgy. With powder metallurgy techniques different types of metal alloys can be produced such as cermets.

The plants that manufacture components out of powder metals are the customers. Method of production is important different powder materials are produced differently. Particle structure characteristics such as size and shape will also be dependent on production method.

Manufacturing Process I Powder Metallurgy Department of Mechanical Engineering Page 2 72 Production of Metallic Powders In general producers of metallic powders are not the same companies as those that make PM parts. The Powder Metallurgy Process. Powder metallurgy routeSource.

Powder Metallurgy comprises a family of production technologies which process a feedstock in powder form to manufacture components of various types. Some materials are produced with more than one technique. Powder metallurgy PM is a metal working process for forming precision metal components from metal powders.

Optional secondary processing often follows to obtain special. For wet milling 30-40 vol of powder with 1 wt of dispersing agent such as water alcohol or hexane is employed. With this process a diemold is still necessary so it shares that similarity with casting although the dies and molds are.

Sinter hardening is a process that can be done as part of the sintering. May be wet or dry wet reduces chances of Explosion. In dry milling about 25 vol of powder is added along with about 1 wt of a lubricant such as stearic or oleic acid.

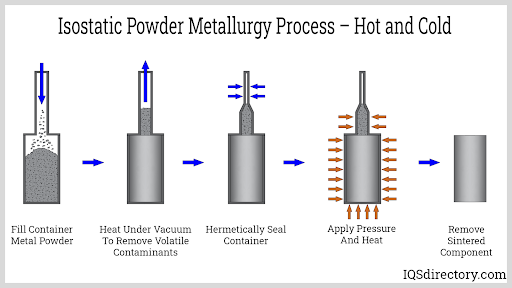

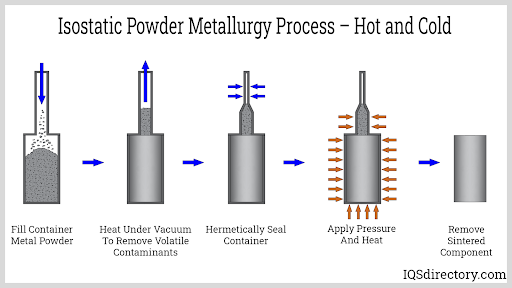

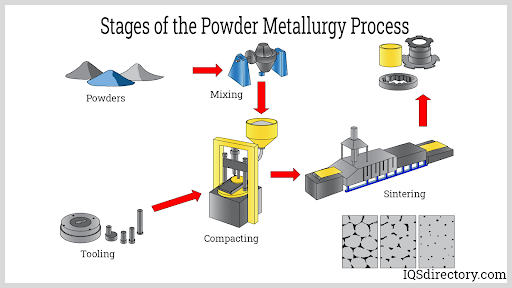

The powder-metallurgy PM process depicted in the diagram below involves mixing elemental or alloy powders compacting the mixture in a die and then sintering or heating the resultant shapes. The temperature at which sintering is performed is lower than the melting point of the powdered material. The powder producers are the suppliers.

Compacting is generally performed at room temperature and the elevated-temperature process of sintering is usually conducted at atmospheric pressure. Heating is executed in a furnace and is called sintering. Its also known as powder processing or sintering.

With powder metallurgy techniques these metals can be used to produce parts. The first step in the overall powder metallurgy PM process is making metal powders. It is also referred to as powder processing considering that non-metal powders can be involved.

Dry semi-dry and wet. These production technologies generally involve all or most of the following process steps. Process grinds the powder materials by impactcollision attrition.

There are four main processes used in powder production. Please see the links to the Metal Powder Industries Federation. In the powder metallurgy precise metal parts are formed with the help of the metal powders.

There are three mixing methods. For example tungsten filaments are produced with powder metallurgy technologies. The whole process in powder metallurgy for manufacturing a part comprises six steps.

The metal powder is first pressed into product shape at room temperature. The purpose is to make a billet of a certain shape and size and have a certain density and hardness. Powder technology is the science for the manufacture of parts from metal powders by compaction and heating that creates a.

In this article you will see sometimes PM instead of the powder metallurgy. The basic Powder Metallurgy process for structural press and sintered components. Milling can be dry milling or wet milling.

This process is mainly used in the production of the unique metals like Tungsten. They are 1 Generation of powder 2 Blending or mixing 3 Compacting 4 Sintering 5 Sizing or impregnation 6 Inspection Generation of powder Powders are manufactured by various methods. Powder metallurgy is generally used for iron based components.

Powders are compacted into a certain geometry then heated sintered to solidify the part. Mixes Particles of different sizes to produce uniform particle distribution. Mixing is the process of mixing various required powders in a certain proportion and homogenizing them to make a compact.

The powder metallurgy process consists of four basic steps. Mixes powders of different. Powder metallurgy is the process of producing components from metal powders.

The process is outlined below. Powder metallurgy is a very neat way to make a component for lack of a better word. Principle of Powder Metallurgy.

The sintering process in powder metallurgy ensures that a part is durable and ready for the trials of real-life use. Manufacture of Powder Metallurgy The size of powder particles normally ranges from 1-100 µm preferably 10-20 µm. Solid-state reduction atomization electrolysis and chemical.

The production of powder of different materials is an essential first step in powder metallurgy. To sinter the component it needs to be heated below its melting point in an atmosphere specifically designed for the selected material and control-cooled. Powder metallurgy is the manufacturing science of producing solid parts of desired geometry and material from powders.

Next the powder is injected into a mold or passed through a die to produce a weakly cohesive structure via cold welding very near the dimensions of the object ultimately to be manufactured. 1Mechanical Process 2Atomization 3Electrolytic Deposition 4Reduction 5Hydride Carbonyl Process 6Condensation of. First the primary material is physically powdered divided into many small individual particles.

The technique of powder metallurgy combines unique technical features with cost effectiveness and generally used to produce sintered hard metals known as carbides or tungsten carbides. This technique deals with the production of metal and non metal powders and manufacture of components. Well that look quite interesting to form the metal parts from the powder.

Powder metallurgy consists three distinct steps ie 1 mixing metal and reinforcement powders 2 powder compaction to produce green materials and 3 sintering usually followed by a deformation process such as hot extrusion Matli et al 2017As a solid-state process powder metallurgy has a lot of advantages including the following items.

Powder Metallurgy Process With Its Advantages And Disadvantages Mech4study

Powder Metallurgy What Is It Processes Parts Metals Used

What Is Powder Metallurgy Definition And Process Engineering Choice

No comments for "Explain Different Process of Powder Metallurgy"

Post a Comment